ATLANTA, GA -- Georgia-Pacific’s commitment to the safety of their employees is on full display at four of their corrugated facilities after earning recognition from the Fibre Box Association (FBA) for their innovative, bottom-up safety solutions.

The Innovation in Safety Achievement Awards aren’t just plaques on a wall — they’re proof that when employees take ownership of safety, real, measurable change happens. From leveraging technology to improving tools and updating procedures based on frontline knowledge.

The Georgia-Pacific Sheet plant in Denton, Texas, installed new Lock Tag Verify (LTV) procedures. LTV is a safety procedure used to ensure machinery and equipment are safely shut off and cannot be accidentally restarted during maintenance or repair. Data from employee memory and outdated documentation were previously used to input the procedures. This allowed for potential preventable employee errors and created a safety risk. The site currently uses digital tablets and the Parsable software to complete other inspections, and they tried an experiment to move LTV procedures to a digital format as well. Now, tablets are used during the LTV process, and each step is carefully documented as it is completed. For critical LTV steps, the system may require photos before employees can move to the next step. This helps bring attention to the process and ensures quality control.

At the Georgia-Pacific Corrugated plant in Owosso, Michigan, the team installed four additional photo eyes, or sensors, at each corner of the transfer cart (T-Cart). Photo eyes project a beam of light that senses for a break in the light’s path. If the light’s path is broken, it sends a signal back to the receiver and effectively stops or slows down the object it’s attached to – in this case, the T-Cart. Originally, the T-Cart only had two photo eyes on either end of its base that would detect obstructions at the floor level as the cart moved down the aisle. With the additional photo eyes, the T-Cart can now also detect objects above floor level including units hanging off a conveyor, forks of a forklift approaching, or a person.

Pictured are the additional photo eyes, or sensors, installed at the Owosso facility that detect objects above floor level including units hanging off a conveyor, forks of a forklift approaching, or a person.

Employees at Georgia-Pacific Corrugated in Huntsville, Alabama installed a bridge walkway from the roof of the facility to the top of the starch silo, eliminating the need to use a straight ladder on the side of the silo which presented a fall potential. Utilizing the hierarchy of controls and the Georgia-Pacific Path to Zero strategy, the facility has reduced their fall risk while allowing employees to perform necessary tasks on the top of the starch silo.

The new bridge walkway at Georgia-Pacific Corrugated in Huntsville, Alabama, eliminated the need to use a straight ladder.

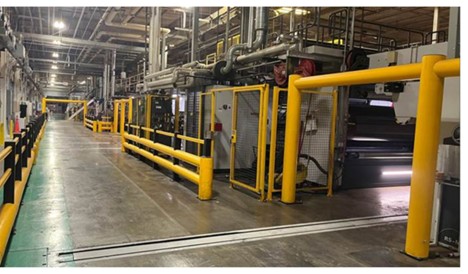

In box plants and sheet feeders, the wet end of the corrugator is a high-risk location. In this area, roll clamps deliver paper rolls right next to employees tasked with manually moving the rolls into the corrugator roll stands. The speed of the corrugator means rolls must be delivered frequently. The team at Georgia-Pacific Packaging in West Chester, Ohio, developed a plan to separate employees from mobile equipment. Permanent barricades were installed that can withstand a roll clamp strike and simultaneously protect employees. The structures also allow a roll of paper to enter, significantly reducing the risk of interaction.

Permanent barricades were installed at Georgia-Pacific Packaging in West Chester, Ohio, that can withstand a roll clamp strike and simultaneously protect employees in a high-risk area.

Georgia-Pacific employees are committed to their own safety and that of their colleagues. Employees not only adhere to processes, procedures and regulations, but also develop and implement plans to ensure safety. |